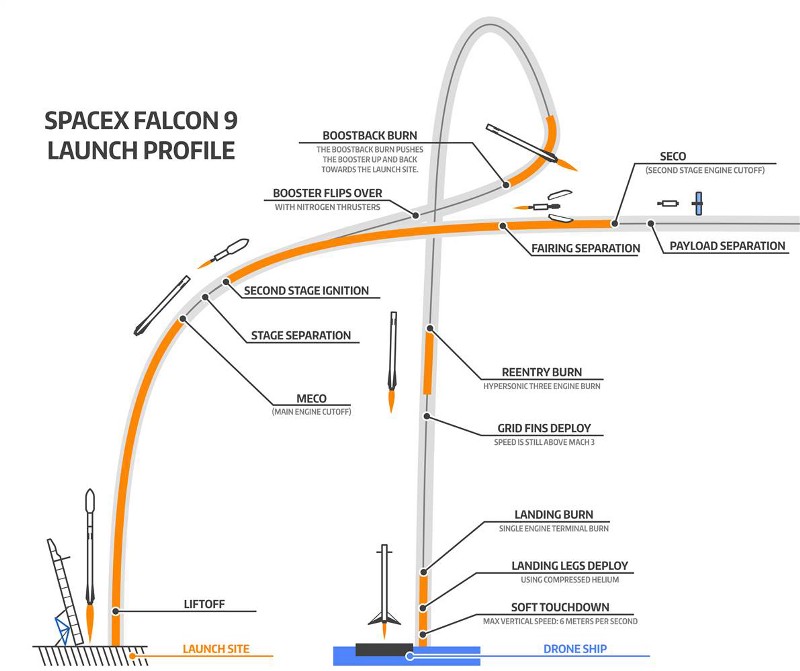

Space travel is expensive, especially since every launch requires a new rocket. The biggest and most costly part is the booster that powers the spacecraft beyond the Earth’s orbit. Once the job, which takes a few minutes, is completed, it separates from the rest of the rocket and drops back into the ocean while the second stage engine takes over and delivers the payload to its destination.

Elon Musk, the CEO of SpaceX, has always maintained that “If one can figure out how to effectively reuse rockets just like airplanes, the cost of access to space will be reduced by as much as a factor of a hundred. A fully reusable vehicle has never been done before. That really is the fundamental breakthrough needed to revolutionize access to space.”

However, recovering a booster without damaging its hardware as it comes zipping back to Earth is easier said than done. Since 2015, SpaceX has been trying to land the first stage rockets vertically on pre-determined landing spots. Before the latest attempt, the company had successfully recovered eight of the twelve rockets launched — three landed on the ground and five on drone ships situated in the middle of the ocean.

On Thursday, March 30, the company went one step further with the first-ever successful launch and landing of a previously used rocket booster. At about 6:27 PM EST, the slightly scuffed and scorched Falcon 9, first used in April 2016 to send food and supplies to the International Space Station, blasted off from the Kennedy Space Center for its sophomore mission. This time, the rocket booster was sending a communications satellite into orbit.

Ten minutes later, after successfully delivering its cargo into space, the rocket booster returned and made a picture-perfect upright landing on the drone ship, dubbed “Of Course I Still Love You,” in the Atlantic Ocean. An elated Musk later gushed, “I’m just incredibly proud of the SpaceX team for being able to achieve this incredible milestone.” The company’s next goal is to refurbish a used rocket so that it is ready for re-launch within 24 hours.

Nobody knows the exact number of times a booster can be reused. Musk speculates it could be anywhere from 10 to 1,000 times depending on the amount of refurbishment required. Given that each reuse saves the manufacturer 30 percent of the $62 million USD cost, or $18 million USD, even being able to send recylce it a few times would yield substantial savings. Suddenly, the idea of heading to space for spring break does not seem as far-fetched!

Resources: Washingtonpost.com, spacex.com,phys.org. verge.com